First update on centrifuge testing

First update on centrifuge testing

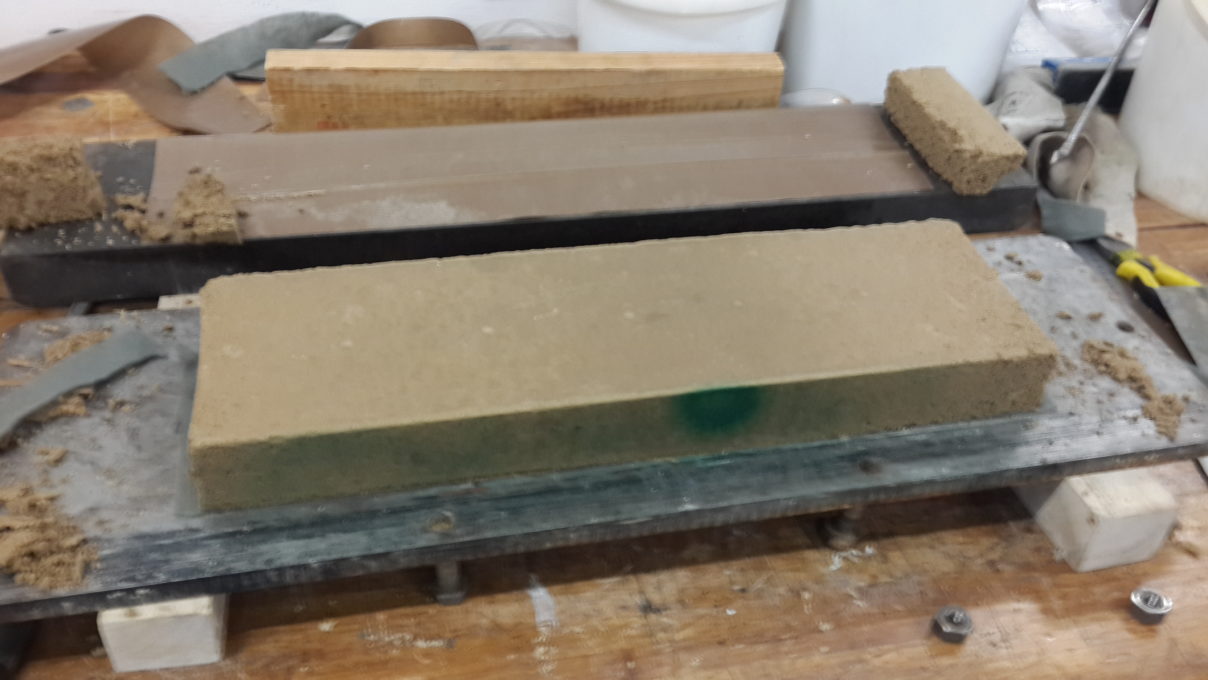

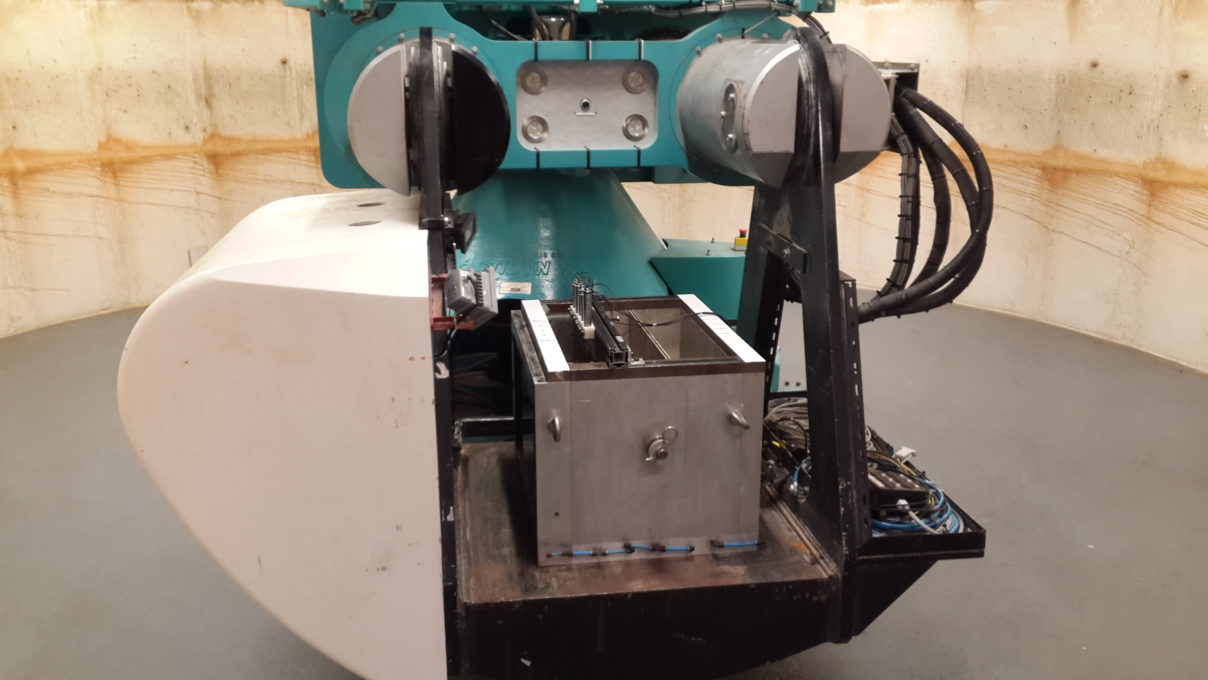

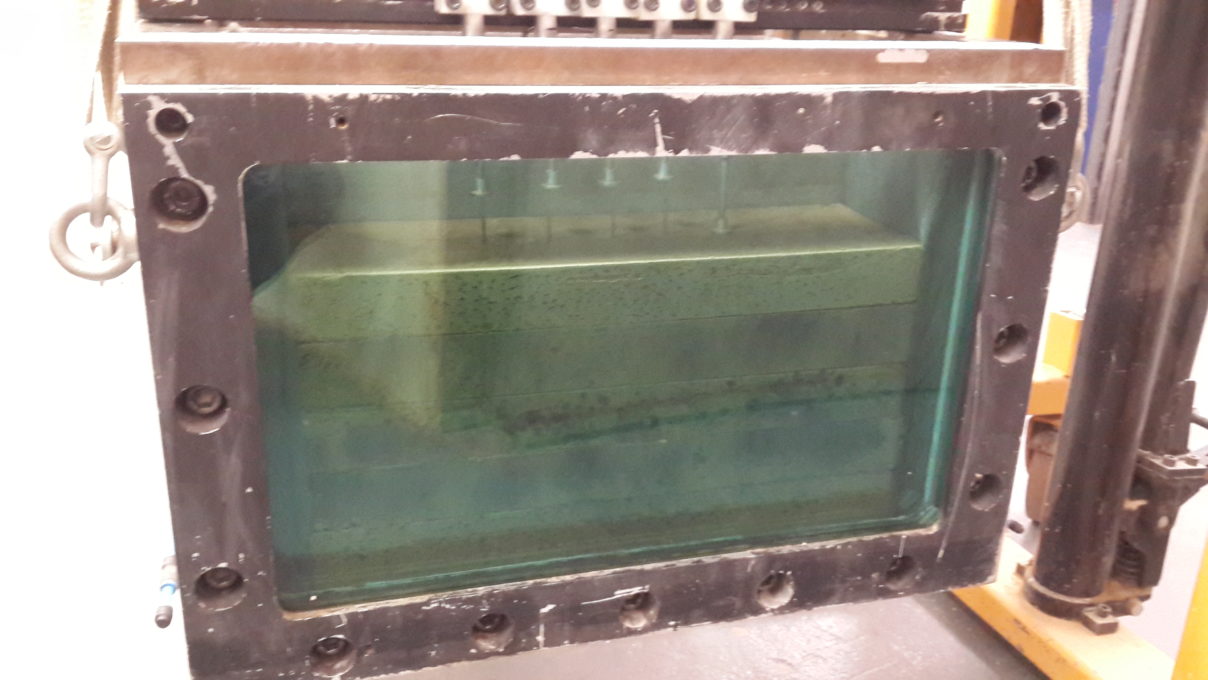

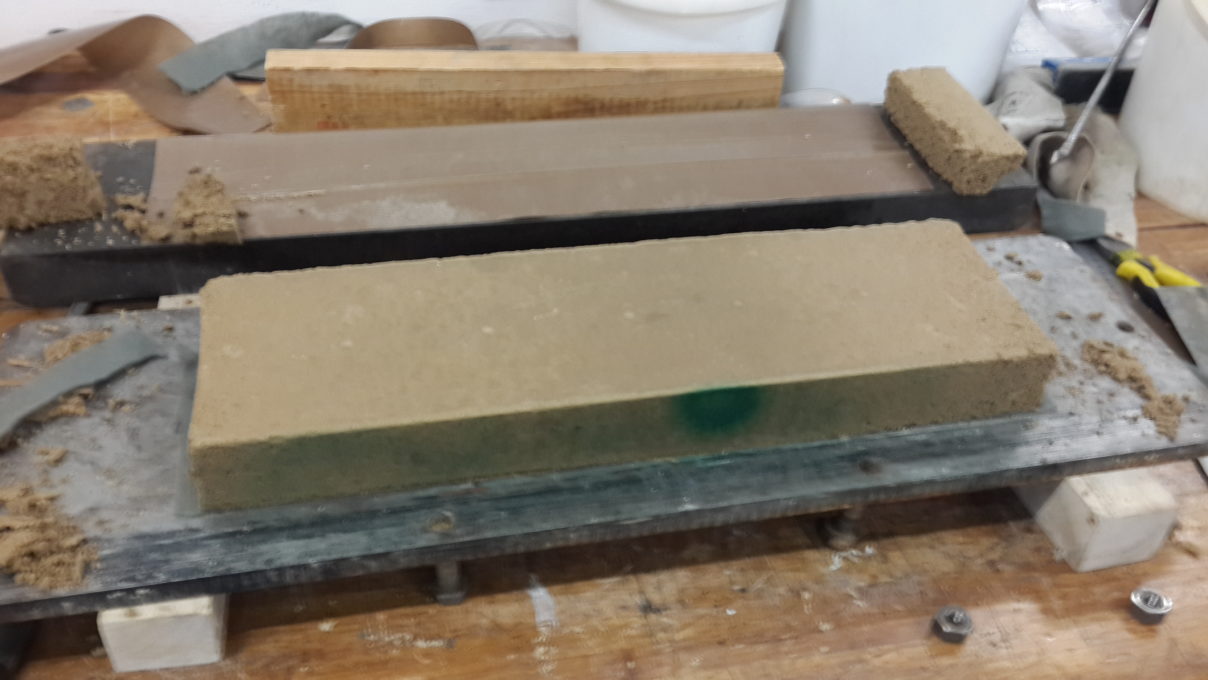

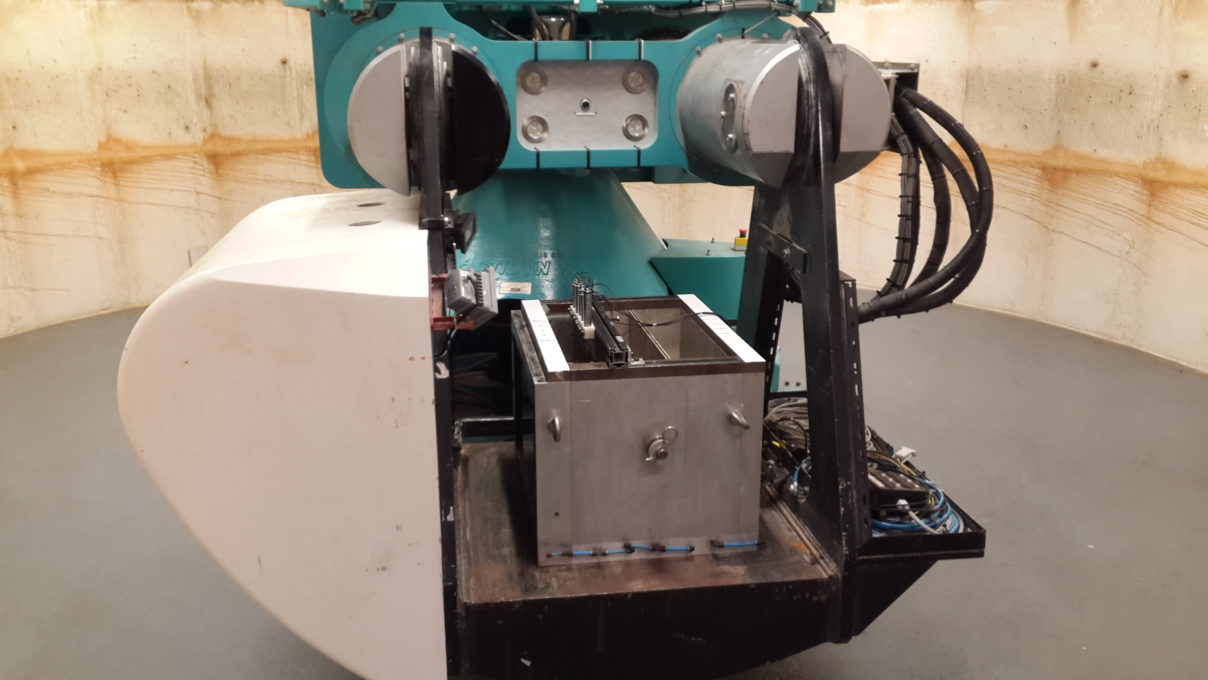

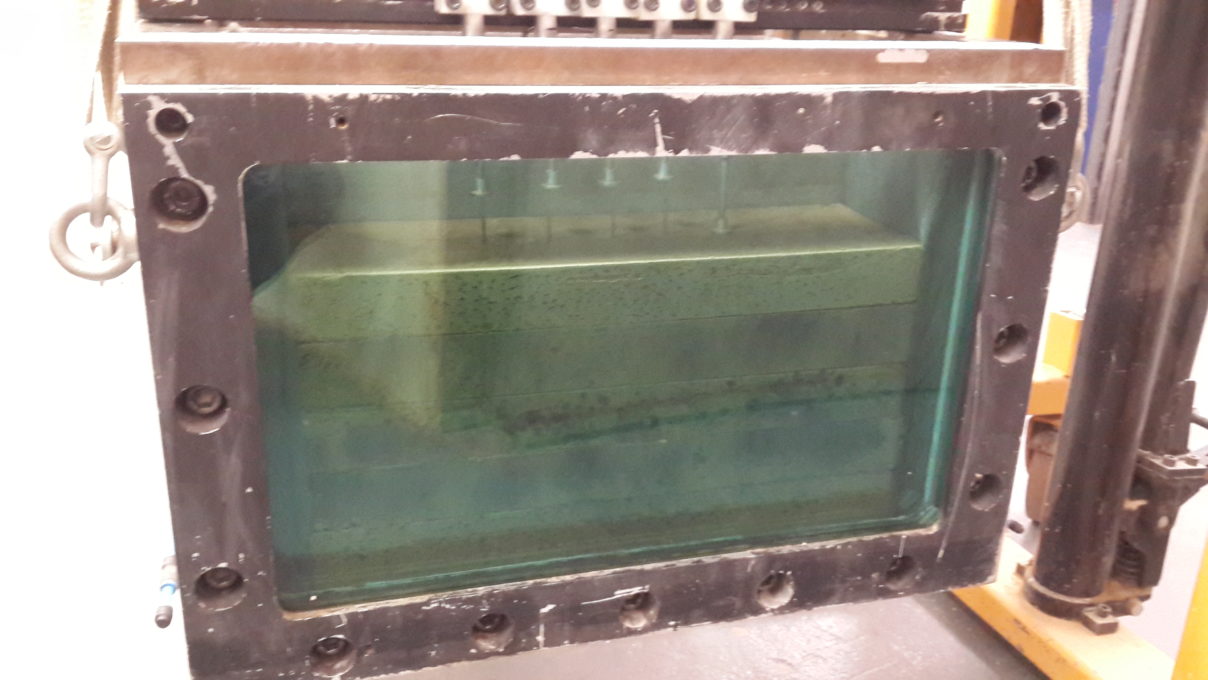

To carry out the first centrifuge tests a number of slabs were created by compressing material at optimum moisture content. The photos below show this procedure:

To carry out the first centrifuge tests a number of slabs were created by compressing material at optimum moisture content. The photos below show this procedure: